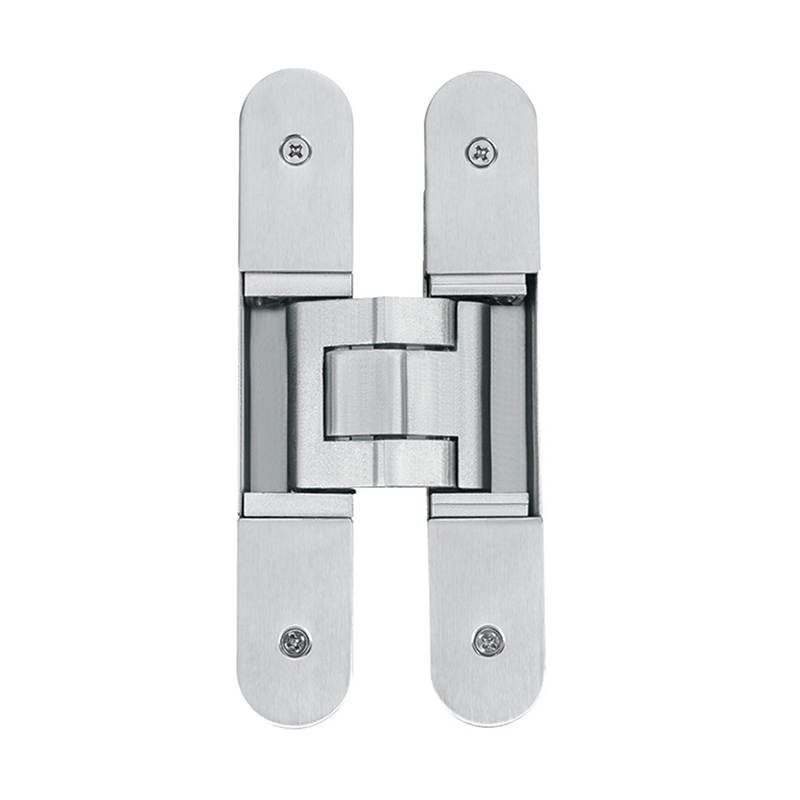

Concealed Exterior Door Hinges is a concealed exterior door hinge designed for modern buildings. It cleverly hides the hinge body behind the door, leaving only a simple mounting plate exposed, bringing an ultimate sense of simplicity to the building's exterior. This hinge is made of high-quality zinc alloy, and the surface is finely sand-chrome treated, presenting a high-grade metallic texture and luster. Its unique 3D adjustable design allows precise fine-tuning in four directions, ensuring the perfect fit between the door leaf and the door frame. After installation, the hinge is almost invisible, perfectly blending into the overall decoration style. Whether it is a residential, commercial building or public facility, Concealed Exterior Door Hinges can enhance the quality of the building and bring users a pleasant experience.

| Item | Parameter |

| Model Number | DSCH015 |

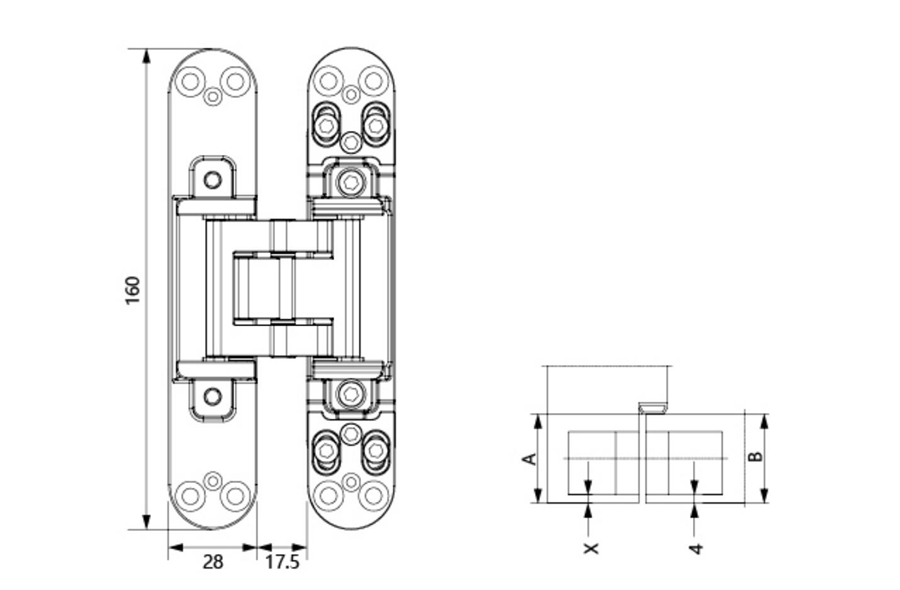

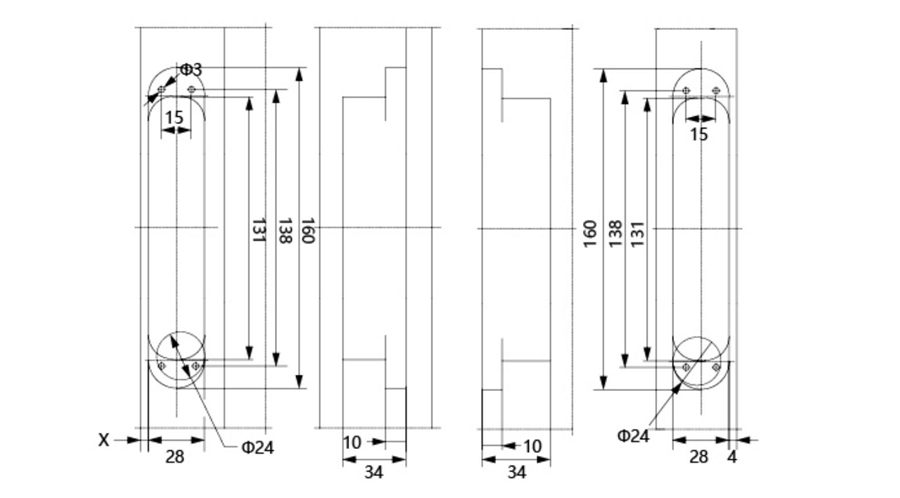

| Size | 160*28mm |

| Material | Zinc Alloy |

Type | 3D Adjustable Concealed Hinge |

| Max. door weight with 2 hinges | 80kg |

| Min. door thickness | 60mm |

| Max. door width | 1000mm |

| Maximum opening angle | 135° |

| Features | Can be realized up and down adiustment + 2.0mm, left and right the adjustment + 2.0mm |

| Surface Treatment | Sand chromium, Sand nickel, Imitation gold, Green ancient, Red ancient |

1. High-quality zinc alloy material

Concealed Exterior Door Hinges are made of zinc alloy, which is an alloy composed of various metal elements such as copper, aluminum, and magnesium, and has good mechanical properties and corrosion resistance. Its tensile strength reaches more than 350 MPa and its elongation exceeds 10%, ensuring that the hinge can withstand the weight of the door and frequent opening and closing actions without deformation in long-term use. After salt spray testing, the hinge did not show any corrosion in the test environment for 72 hours, proving its durability in humid environments. Compared with ordinary iron hinges, the zinc alloy material is 30% lighter, which reduces the opening resistance of the door while ensuring strength, making the door opening and closing easier and smoother.

2. Super Durability

This hinge has undergone rigorous quality testing and can withstand door weights of up to 80 kg. After 100,000 simulated opening and closing cycles, it can still maintain stable performance and structural integrity. The precision bearing design inside ensures low friction and high-precision operation of the door during opening and closing, effectively reducing mechanical wear. In daily use, even in the face of frequent use and heavy door weight, the hinge will not loosen or make abnormal noises, providing users with long-term and reliable use guarantees. For example, at the entrance of a public building with a large flow of people, after a long period of use, the hinge can still maintain the normal opening and closing function of the door without frequent maintenance or replacement.

3. Excellent corrosion resistance

The surface treatment process of Concealed Exterior Door Hinges is exquisite, using a variety of advanced surface treatment technologies such as sand chrome and sand nickel. Taking sand chrome treatment as an example, a 0.008 mm thick chromium layer is formed on the surface. This chromium layer not only gives the hinge a bright appearance, but also has extremely strong corrosion resistance. The corrosion resistance of the chromium layer comes from its self-repairing ability. When the surface is slightly scratched or worn, the chromium layer can re-form a protective film through oxidation reaction to continue to resist external corrosion factors. In actual application, the hinge can resist the erosion of corrosive environments such as seawater, industrial waste gas, acid rain, etc., and its service life can reach more than 15 years, which is far longer than the 3-5 years of ordinary galvanized hinges, significantly reducing long-term maintenance costs.

4. Concealed exquisite design

The hidden design of Concealed Exterior Door Hinges is the biggest highlight of its appearance. The hinge body is cleverly hidden between the door leaf and the door frame, and only two mounting plates with a thickness of 160 mm and a width of 28 mm are exposed behind the door. The surface of the mounting plate adopts a rounded corner design, the edge is smooth and burr-free, and it fits perfectly with the wall or decorative layer behind the door, and almost does not occupy indoor space. This design not only improves the overall aesthetics of the building, but also avoids damage to traditional exposed hinges caused by collision or friction. In some places with high requirements for decoration style, such as high-end residences, luxury hotels, modern offices, etc., the hidden hinge can be seamlessly integrated with the overall decoration style, adding a sense of luxury and modernity to the space.

5. 3D Adjustability

This hinge has excellent 3D adjustability, which provides great convenience for installation and later adjustment. The up and down adjustment range can reach ±2.0 mm, and the left and right adjustment range is also ±2.0 mm, which can accurately solve the gap problem between the door leaf and the door frame, ensuring that the door leaf fits tightly with the door frame when closed, achieving good sound insulation and sealing effects. The adjustment operation is simple and convenient. There is no need to disassemble the hinge. Just use professional tools to make fine adjustments through the adjustment holes on the mounting plate. For example, when the door frame is slightly deformed due to seasonal changes or humidity, the user can adjust the hinge by himself to restore the normal opening and closing state of the door, avoiding problems such as ventilation and light transmission caused by excessive or too small door gaps, and also reducing the noise caused by the collision between the door leaf and the door frame.

6. Multiple surface treatment processes

Concealed Exterior Door Hinges provide a variety of advanced surface treatment options to meet different decoration styles and user needs. In addition to the common sand chrome and sand nickel treatments, there are also antique gold, green bronze, red bronze and other colors to choose from. Each surface treatment process is strictly quality controlled to ensure uniform color, strong adhesion and good wear resistance. For example, the antique gold surface treatment uses a special electroplating process to form a 0.01 mm thick gold coating on the zinc alloy surface. It not only looks simple and elegant, but also has good anti-fingerprint performance. It is not easy to leave obvious fingerprints or stains in daily use, and maintenance is easier. A variety of color options allow the hinge to be perfectly matched with door leaves and door frames of various materials and colors, providing greater creative space for architectural design and interior decoration.

7. Precision manufacturing process

Concealed Exterior Door Hinges use advanced manufacturing processes to ensure that every component meets high-precision standards. Its internal linkage mechanism is processed by high-precision CNC machine tools, and the matching clearance of each component is controlled within 0.02 mm, which ensures the stability and smoothness of the door during opening and closing. The connection between the mounting plate and the hinge body uses high-strength stainless steel screws, and the torque of each screw is precisely controlled to ensure the firmness and reliability of the connection. During the assembly process, a combination of automated production lines and manual quality inspection is used to conduct strict quality inspections on each finished hinge, including opening and closing force tests, adjustment function tests, durability tests, etc., to ensure that each hinge leaving the factory can meet the design requirements and quality standards, and provide users with high-definition and stable performance.

8. Wide range of applicable sizes

Concealed Exterior Door Hinges are designed for door leaves of various sizes, and can meet the installation requirements of a minimum door thickness of 60 mm and a maximum door width of 1000 mm. This wide range of applicable sizes makes it suitable for most common door leaf types, whether it is indoor doors and entrance doors in residential buildings, or fire doors and soundproof doors in public buildings, etc., you can find suitable matching hinges. During installation, users only need to select the corresponding hinge model according to the actual size of the door leaf, and follow the standard installation steps to quickly complete the installation work. Compared with customized hinges, the standardized design of this series of hinges not only reduces production costs, but also shortens the delivery cycle, providing a strong guarantee for the smooth progress of construction projects.

1. High-end residential interior doors

In high-end residences, Concealed Exterior Door Hinges are an ideal choice for improving the quality of interior decoration. Its hidden design and diverse surface treatment processes can perfectly adapt to various high-end decoration styles, from modern simplicity to European classical, from Chinese tradition to Nordic style, all of which can complement the door leaf and the overall decoration style. For example, in a house decorated in a modern and simple style, a concealed hinge with a sand chrome surface treatment is installed. Only a simple installation plate is exposed behind the door, which is integrated with the wall decorative lines. The overall space appears more spacious and bright, and the sense of lines is stronger. In daily use, residents can feel that the door opens and closes smoothly, the mute effect is excellent, and the gap between the door leaf and the door frame is uniform and beautiful, which effectively improves the comfort and satisfaction of living. According to statistics, in the high-end residential market, the proportion of interior doors using concealed exterior door hinges has reached 65%. User feedback shows that this type of hinge has significant advantages in improving the aesthetics of the home and the user experience.

2. Luxury hotel guest room doors

Luxury hotels have extremely high requirements for the aesthetics and functionality of guest room doors. Concealed Exterior Door Hinges have become the first choice for many luxury hotels due to their excellent performance and appearance design. Its 3D adjustable function can ensure that the guest room door still maintains good closing effect and sealing performance after frequent use, effectively isolates external noise and light, and provides guests with a quiet and comfortable resting environment. At the same time, a variety of surface treatment processes can meet the needs of hotel designers for different decoration themes. For example, in a luxury hotel with a modern art style theme, the guest room door uses a concealed hinge with an antique gold surface treatment. The golden luster of the mounting plate behind the door echoes the metal decorative elements in the guest room, creating a luxurious and warm atmosphere. The hotel management reported that since the use of this hinge, the maintenance rate of the guest room door has been reduced by 40%, and the guest satisfaction score has increased by an average of 15 points, which has effectively improved the overall service quality of the hotel.

3. Commercial office building entrance door

In commercial office buildings, the entrance door is used very frequently, which poses a severe challenge to the durability and stability of the hinge. Concealed Exterior Door Hinges can easily meet this demand with its super load-bearing capacity and durability. Take a large commercial office building as an example. Its entrance door uses this series of hinges. The door weight reaches 75 kg and the door width is 1000 mm, which meets the maximum load-bearing and size range of the hinge. After one year of use, the hinges are still in good working condition with an average opening and closing frequency of more than 200 times a day, without any looseness or damage. In addition, the hidden design makes the entrance door look simple and elegant, which enhances the professional image of the building. During the peak office hours with large personnel flow, the smooth opening and closing of the door effectively avoids congestion and safety hazards, providing reliable protection for the daily operation of commercial office buildings.

4. Partition doors for medical institutions

When designing partition doors, medical institutions need to take into account multiple functional requirements such as sound insulation, sealing, and easy cleaning. The excellent sealing performance and 3D adjustability of Concealed Exterior Door Hinges make it an ideal choice for partition doors in medical institutions. Its maximum opening angle can reach 135°, providing sufficient space for medical staff and patients to enter and exit. At the same time, when closed, the close fit between the door leaf and the door frame can effectively isolate noise and dust to prevent cross infection. This series of hinges was used in the ward partition door renovation project of a tertiary hospital. After field testing, the noise level in the ward was reduced by about 10 decibels, and the air cleanliness was improved by 20%, creating a quieter and more hygienic rehabilitation environment for patients. Medical staff reported that the partition door has a high degree of smooth opening and closing, is easy to adjust, and does not require additional maintenance in daily use, which significantly improves work efficiency and patient satisfaction.

5. Classroom doors of educational institutions

The classroom doors of educational institutions need to be opened and closed frequently, and the use environment is relatively complex, which requires high durability and safety of hinges. The zinc alloy material and precision manufacturing process of Concealed Exterior Door Hinges ensure its stability and reliability in long-term use, and can withstand the frequent operation and occasional collisions of students entering and leaving the classroom on a daily basis. Its concealed design avoids the risk of scratches or pinching hands that traditional exposed hinges may cause to students, providing additional protection for campus safety. For example, in a classroom door renovation project of a key middle school, concealed hinges with sand nickel surface treatment were installed. After one semester of use, all the hinges of the classroom doors did not have any quality problems, and the door opening and closing performance was good, effectively reducing the interference to students' attention caused by door shaking or abnormal noise, and improving the classroom teaching environment.

6. Industrial plant and warehouse doors

The doors of industrial plants and warehouses are usually large in size and in a harsh environment, which places high demands on the bearing capacity and corrosion resistance of the hinges. The maximum bearing capacity of Concealed Exterior Door Hinges reaches 80 kg, which can meet the installation requirements of most industrial plant and warehouse doors. Its excellent corrosion resistance enables it to maintain good working condition in the face of complex conditions such as chemical volatilization and humidity changes in industrial environments. Take the warehouse door of a chemical enterprise as an example. The door is 80 mm thick and 950 mm wide. After installing this series of hinges, after two years of use, the hinges have not rusted or damaged, and the door can still open and close smoothly. The use of this type of hinge effectively solves the problem of easy damage and high maintenance costs of ordinary hinges in industrial environments, providing strong support for the normal production and operation of the enterprise.

1. Daily cleaning and maintenance

To ensure the cleanliness and good appearance of the Concealed Exterior Door Hinges, it is recommended to perform daily cleaning and maintenance once a week. Use a soft dry or slightly damp cloth to gently wipe the surface of the mounting plate to remove dust, fingerprints and stains. For stains that are more difficult to clean, you can use a neutral detergent, such as dishwashing liquid diluted with water in a ratio of 1:20, dip the solution into a soft cloth and gently wipe the stain, then rinse with clean water and dry thoroughly. Avoid using detergents containing abrasives, strong acids or strong alkalis to avoid scratching the surface treatment layer or causing corrosion. Regular cleaning can not only maintain the beauty of the hinges, but also detect potential surface problems such as scratches, fading, etc. in time, so that appropriate repair measures can be taken in time.

2. Regularly check the adjustment function

Regularly check the adjustment function of the Concealed Exterior Door Hinges every month to ensure that the gap between the door leaf and the door frame is uniform and meets the design requirements. When checking, close the door leaf first and observe whether the gap between the door leaf and the door frame is uniform. If there is an uneven or too large gap, use professional tools to fine-tune the hinge in time. The adjustment operation should be gentle and smooth, and avoid excessive force that may damage the internal adjustment mechanism. During the adjustment process, pay attention to record the changes before and after the adjustment so that you can reset and adjust when necessary. Regular inspection and adjustment can ensure the sealing performance and sound insulation effect of the door, and at the same time extend the service life of the hinge and reduce damage caused by collision or friction between the door leaf and the door frame.

3. Lubrication and maintenance

Lubricate and maintain the Concealed Exterior Door Hinges once a quarter to ensure the smooth operation of its internal mechanical structure. Use special door hinge lubricant or light engine oil, and apply the lubricant evenly to the active parts of the hinge, such as bearings, linkage rods, etc. during the opening and closing of the door. Avoid using too much lubricant to prevent oil stains from overflowing and contaminating the door leaf or wall. After applying the lubricant, open and close the door leaf several times to allow the lubricant to fully penetrate the internal mechanical structure, and then wipe off the excess oil with a clean cloth. Lubrication maintenance can effectively reduce the friction inside the hinge, reduce mechanical wear, and improve the smoothness and quietness of the door opening and closing. Lubrication maintenance is particularly important in dry seasons or when used frequently.

4. Moisture-proof and rust-proof measures

In a humid environment, Concealed Exterior Door Hinges need to take additional moisture-proof and rust-proof measures to ensure their long-term stable operation. In the rainy season or near water sources, it is recommended to apply a thin layer of anti-rust oil or vaseline on the hinge surface to form a protective film to isolate moisture from the metal surface. At the same time, ensure good ventilation behind the door to avoid condensation due to poor air circulation. In some coastal areas that are susceptible to seawater erosion, professional rust inhibitors can be used regularly to treat the hinges. According to the requirements of the product manual, spray the rust inhibitor evenly on the hinge surface and wait for it to dry to form a solid protective layer. After taking moisture-proof and rust-proof measures, the corrosion resistance of the hinge will be significantly improved, and the service life can be extended by 30% - 50%, effectively reducing the maintenance and replacement costs caused by humid environments.

5. Regularly check the installation stability

Every six months, conduct a comprehensive inspection of the installation stability of the Concealed Exterior Door Hinges to ensure that its connection with the door leaf and door frame is firm and reliable. Carefully check whether the screws on the mounting plate are loose. If there are signs of looseness, use the corresponding tools to tighten them to the appropriate torque. Check whether the connection between the door frame and the wall is stable. If there is displacement or looseness, the door frame should be reinforced or the wall structure should be repaired in time. During the inspection, pay attention to whether there are cracks or deformations between the hinge body and the mounting plate. If found, contact professional maintenance personnel in time for replacement. Regular inspection of installation stability can timely discover and solve potential safety hazards, avoid damage to the door leaf or safety accidents caused by loose or falling hinges, and ensure the personal safety and property safety of users.

6. Professional maintenance and regular replacement

It is recommended to conduct a professional maintenance inspection on Concealed Exterior Door Hinges every year. You can contact a professional hardware accessories maintenance organization or manufacturer to conduct a comprehensive performance test and maintenance of the hinges. Professionals will use advanced testing equipment and technology to comprehensively evaluate the load-bearing capacity, adjustment accuracy, corrosion resistance and other indicators of the hinges, timely discover potential problems and carry out targeted repairs. At the same time, according to the actual use and wear of the hinges, it is determined whether some parts need to be replaced or the whole needs to be updated. Generally speaking, even if the hinge has a long service life under normal use, it is recommended to consider replacing it with a new hinge after 10-15 years of use to ensure that its performance and safety are always in the best condition, providing reliable protection for the normal opening and closing of the building door and the safety of the user. Users can keep the maintenance and replacement records so that relevant historical information can be provided when necessary to assist professionals in more accurate evaluation and treatment.

Our concealed hinges are made from high-grade zinc alloy, ensuring durability and resistance to corrosion, which is vital for maintaining the integrity of fire doors.

These hinges are versatile and can be used with a wide range of fire door types, including wooden, steel, and composite doors, making them suitable for various applications.

Since the hinges are concealed when the door is closed, they provide a seamless look that enhances the door's aesthetic appeal by not interrupting the surface design or finish.

Minimal maintenance is required. A periodic check for alignment and a light application of non-combustible lubricant is recommended to keep the movement smooth and maintain the integrity of the hinge function.

Definitely, doors come in different sizes and weights and that is why we have designed hinges of different sizes and configurations. Our engineering team can also develop custom solutions for special application needs.