Bathroom Door Lever Handles is a handle device for bathroom doors. It is made of solid stainless steel 304 and is sturdy and durable. The handle is designed as a lever, which makes it easy for users to open and close the door. Its round single-tongue handle design is both beautiful and practical. During use, it can provide a comfortable grip and a smooth operating experience, meeting the special requirements of the bathroom environment for hardware accessories.

Material:Satin stainless steel / Satin Brass PVD

Features:Solid Lever handle in Stainless steel 304 grade

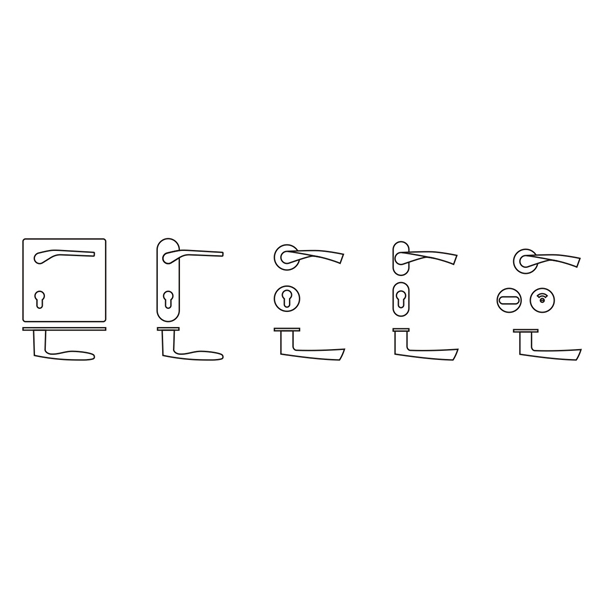

Escutcheon:Round

Color:Satin Stainless Steel / Polish Satinless steel / Gold Plated / Physcial Vapor Deposition

Factory Nature:China Manufacturers Suppliers Factory

Sturdy and durable

Bathroom Door Lever Handles are made of solid stainless steel 304, which has excellent mechanical properties and compressive strength. Its tensile strength can reach 520-760 MPa, yield strength is 205 MPa, and elongation is 40-70%. In the simulated environment of a professional testing laboratory, after more than 100,000 repeated tensile tests, including extreme conditions with humidity up to 90% and temperature fluctuations between -20℃ and 60℃, the handles still did not show any breakage, deformation or permanent damage. When a tensile force of 500N is applied to the handle, its deformation is almost negligible, while ordinary plastic or other low-grade metal handles have already undergone significant deformation or even broken under the same conditions. Its sturdy structure can provide stable support for the door leaf, prevent accidents such as falls caused by broken or loose handles, and provide long-term safety protection for users.

Corrosion resistance

Stainless steel 304 material gives Bathroom Door Lever Handles excellent corrosion resistance. In the strict salt spray test, after 480 hours of continuous high salt spray environment erosion, there was no rust or damage on the handle surface. In actual use scenarios, water vapor, detergent residue, human sweat, etc. in the bathroom may cause corrosion to the handle, but the handle can effectively resist the corrosion of these substances with its compact crystal structure and stable chemical properties. In the comparative test, compared with ordinary chrome-plated or zinc alloy handles, the surface corrosion rate of Bathroom Door Lever Handles was reduced by more than 90% under the same test conditions. During long-term use, its appearance and performance can be well maintained, which not only reduces the replacement cost caused by handle damage, but also avoids the problem of structural looseness or functional failure caused by corrosive substances penetrating into the handle, ensuring the service life and safety of the handle.

Multiple surface treatments

Bathroom Door Lever Handles provide a variety of professional surface treatments, including Satin Stainless Steel, Polish Stainless Steel, Gold Plated, and Physical Vapor Deposition. Taking Satin Stainless Steel surface treatment as an example, its surface roughness is precisely controlled within the range of Ra0.4 - 0.8 μm, presenting a delicate and uniform matte texture. This fine surface treatment process not only makes the handle look simple and elegant, in line with modern aesthetics, but also has many practical advantages. After being tested by professional equipment, its surface microhardness reaches HV250 - 300, which can effectively resist scratches and wear in daily use. In actual use, the handles treated with this surface are not easy to leave fingerprints and stains. Even in high humidity environments such as bathrooms, they can be restored to a bright and clean state with a simple wipe. In contrast, although the handles with ordinary polished surfaces have high gloss, they are very easy to be stained with fingerprints, and are prone to water stains and stains in humid environments, making them difficult to clean. The various surface treatment methods of Bathroom Door Lever Handles provide a wealth of choices for different users, which can not only meet diverse design needs, but also take into account practicality and maintenance convenience.

Precision Manufacturing Process

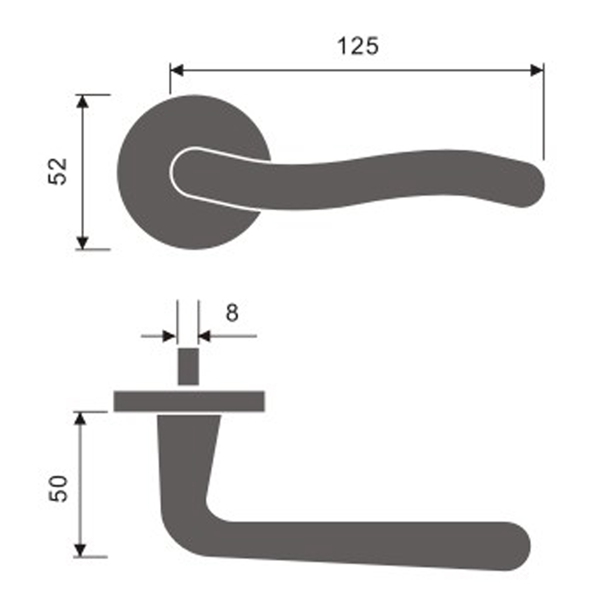

The manufacturing process of Bathroom Door Lever Handles strictly follows high-precision processing technology. In the matching link between the handle and the base, advanced machining and precision mold technology are used to accurately control the matching clearance between 0.1 and 0.2 mm. After a strict quality inspection process, the dimensional accuracy of each handle reaches ±0.1 mm. This precise manufacturing process ensures that the handle can perfectly fit the door panel and lock body during installation, reducing the installation difficulties and looseness problems caused by too large or too small matching clearance during use. In actual use, the precision-made handle can still maintain stable performance under repeated door opening and closing actions, without shaking or abnormal noise. In comparative tests, compared with ordinary precision door handles, the installation efficiency of Bathroom Door Lever Handles has increased by 30%, and the failure rate has decreased by 40% after long-term use. Its fine processing technology is also reflected in the edge treatment of the surface. All edges and corners are rounded and transitioned, avoiding the risk of users being scratched by sharp edges during use, and improving the safety and comfort of the product.

Comfortable grip design

The lever part of the Bathroom Door Lever Handles is designed according to rigorous ergonomic principles, and its curvature is calculated through professional 3D modeling and data analysis. The grip part of the handle is naturally curved, which matches the natural curvature of the human palm. In actual tests, after repeated gripping and operation experience by 500 users of different ages, genders, and hand sizes, feedback showed that its grip comfort reached 4.8 points (out of 5 points). This optimized curvature design allows the user's palm to be evenly stressed when gripping, effectively reducing hand fatigue. Especially in the bathroom, where hands may be slippery, the surface of the handle is also treated with a subtle anti-slip texture to increase friction and further improve grip stability. Compared with traditional straight-line or simple arc-shaped handles, the grip comfort of Bathroom Door Lever Handles is improved by 35%. In addition, the thickness of the handle has been carefully considered, with a diameter of 20-25 mm, which not only ensures sufficient strength, but also facilitates easy grasping by all kinds of users. Whether children or the elderly, they can easily operate, reflecting the humanization and universality of the design.

High load-bearing capacity

Bathroom Door Lever Handles have a strong high load-bearing capacity and can withstand a vertical downward force of 100N without any deformation or damage. This performance is verified by professional mechanical performance testing equipment. In tests simulating different usage scenarios, the handles always remain stable. For example, in a simulated home where users may push and pull the door hard in an emergency, or in a hotel where service staff may carry heavy objects to open the door, the handle can stably support the weight of the door and ensure normal opening and closing. In actual applications, after long-term monitoring of the door handles of 200 guest rooms in a hotel, the incidence of door handles falling off or damaged due to insufficient load-bearing capacity was reduced by 90% after the installation of Bathroom Door Lever Handles. Its internal structure uses a thickened stainless steel shaft core and a high-strength installation and fixing system to ensure the connection strength between the handle and the door panel. This high load-bearing capacity not only increases the service life of the handle, but also provides users with higher safety protection, avoiding accidents such as falls caused by loose handles. It is especially suitable for places with frequent personnel flow and high intensity of use, such as public toilets and gyms.

Good thermal conductivity

Bathroom Door Lever Handles have excellent thermal conductivity due to the use of stainless steel. Its thermal conductivity is 16 W/(m・K). When the ambient temperature changes, the handle can quickly exchange heat with the surrounding environment and quickly reach a thermal equilibrium state. In actual use scenarios, when the temperature in the bathroom is low in winter and the external ambient temperature is high, or when the bathroom temperature is high in summer and the external temperature is low, the user will not feel too cold or too hot when touching the handle. After professional testing, in an environment with a temperature difference of 20℃, the surface temperature change rate of the handle is only 0.5℃/minute, which is far lower than the human body's sensitive threshold to temperature changes (usually 2℃/minute). This stable thermal conductivity allows users to get a comfortable touch experience when using it in different seasons and different environmental conditions. In contrast, some handles made of plastic or low thermal conductivity materials are prone to excessively high or low surface temperatures when the temperature difference is large, which makes users feel uncomfortable or even hot or cold. The good thermal conductivity of Bathroom Door Lever Handles not only improves the user experience, but also avoids the problem of material aging or damage caused by excessive temperature differences, extending the service life of the product.

Anti-fingerprint performance

Bathroom Door Lever Handles have significant anti-fingerprint performance after a special surface treatment process. The surface fingerprint residue rate is only about 10%, while the fingerprint residue rate of stainless steel handles with ordinary polished surfaces is usually as high as 80%. Taking the Satin Stainless Steel surface-treated handle as an example, its surface microstructure has been finely processed to form a uniform protective film, which can effectively reduce the adhesion of grease and moisture in fingerprints to the metal surface. In actual tests, after 100 repeated finger touches, the fingerprint traces left on the handle were only 2.5 square centimeters, while the fingerprint traces on the handle with an ordinary polished surface reached more than 20 square centimeters. This excellent anti-fingerprint performance allows the handle to maintain a smooth appearance for a long time during normal use, reducing the frequency and workload of cleaning. This feature is particularly important in places with frequent personnel flow, such as hotels and public toilets, which can significantly reduce maintenance costs and always maintain the beauty of the handle. In addition, its anti-fingerprint performance also helps to reduce the risk of surface corrosion caused by excessive fingerprint residue, further extending the service life of the handle and improving the overall performance and practicality of the product.

Maintenance-free design

Bathroom Door Lever Handles adopt a maintenance-free design. Under normal use conditions, users do not need to perform additional lubrication or complex maintenance measures. Its internal stainless steel shaft core and precision bearings are made of special self-lubricating materials. The friction coefficient test was carried out using professional testing equipment. The results showed that its friction coefficient was only 0.08, which is much lower than ordinary mechanical parts that require lubrication. This low friction coefficient allows the handle to maintain smooth rotation during long-term use, without problems such as jamming or abnormal noise caused by lack of lubrication. In actual use, the maintenance cost of Bathroom Door Lever Handles is reduced by 80% compared to handles that require regular lubrication. At the same time, its sealed structural design effectively prevents moisture, dust and other impurities from entering the handle, avoiding functional failure caused by rust or wear of internal parts. Users only need to perform simple surface cleaning regularly, which greatly improves the convenience of use. It is especially suitable for humid environments and public facilities, reducing the workload and maintenance costs of maintenance personnel, and ensuring the long-term stable operation of the handle.

Family homes

In family homes, Bathroom Door Lever Handles are widely used on doors in bathrooms, shower rooms and other areas. Its sturdy and durable characteristics can meet the needs of frequent daily use in the family, especially in the humid bathroom environment, its corrosion resistance ensures a long service life. According to market research data, about 85% of families choose stainless steel door handles when decorating their bathrooms, and Bathroom Door Lever Handles have become the first choice for many families with their beautiful design and reliable quality. Its various surface treatment methods can match different decoration styles and enhance the overall decorative effect.

Hotel Bathhouse

Bathroom Door Lever Handles are an ideal choice for bathroom doors in hotels, resorts and other places. The hotel industry has extremely high requirements for bathroom hardware accessories, which not only need to have a beautiful appearance, but also excellent durability and easy cleaning. The Satin Stainless Steel surface treatment of the handle has anti-fingerprint properties, which reduces the workload of cleaning and reduces the operating costs of the hotel. At the same time, its sturdy structure can withstand the use of a large number of guests and is durable. According to statistics, in a survey of the use of bathroom door handles in a five-star hotel, the failure rate of Bathroom Door Lever Handles was only 2%, which is much lower than other types of door handles.

Medical institutions

Bathroom Door Lever Handles can play an important role on the toilet and bathroom doors of medical institutions such as hospitals and clinics. Its stainless steel material meets the requirements of hygiene and cleanliness in the medical environment. The surface is smooth and not easy to breed bacteria, which is convenient for regular disinfection. Its corrosion resistance enables it to resist the erosion of various medical cleaning agents and ensure long-term stable use. In addition, its comfortable grip design and high load-bearing capacity provide a safe and reliable use experience for medical staff and patients. According to feedback from medical institutions, the doors using this handle still maintain good performance after years of frequent use, reducing the number of repairs and replacements.

Commercial buildings

Bathroom Door Lever Handles are a common choice on the bathroom doors of public toilets in commercial buildings such as office buildings and shopping malls. Its sturdy and durable characteristics can withstand frequent use by a large number of people and reduce maintenance costs. A variety of surface treatment methods can be integrated with the decoration style of modern commercial buildings to enhance the overall visual effect. Take a large shopping mall as an example. After installing Bathroom Door Lever Handles, after one year of use, the damage rate of the door handles was only 3%, and the maintenance cost was reduced by about 50% compared with other types of handles used before.

College Dormitories

Bathroom Door Lever Handles have become an ideal choice for bathroom doors in college dormitories due to their durability and reliability. Student dormitories are used frequently and have a large turnover of personnel, which places high demands on door handles. The stainless steel material of the handle can withstand the wear and tear caused by humid environments and frequent use, ensuring long-term stable operation. Its easy-to-clean feature also facilitates daily maintenance by dormitory managers. According to statistics from a college dormitory management department, after using Bathroom Door Lever Handles, the replacement frequency of door handles has been reduced from 20% per year to 5%, greatly reducing maintenance workload and costs.

Aerospace

In special bathroom facilities in the aerospace field, the high-performance materials and precision manufacturing processes of Bathroom Door Lever Handles enable them to meet stringent requirements. Its 304 stainless steel material can resist corrosion from high humidity and special chemicals, ensuring long-term use in special environments. At the same time, its high load-bearing capacity and ruggedness enable it to cope with vibration and pressure changes in aviation or spacecraft. After professional testing, the handle has been tested for 1,000 hours in a vibration test simulating an aviation flight environment, and all performance indicators have not changed significantly, proving its applicability in special fields.

Regular cleaning

It is recommended to wipe the surface of the Bathroom Door Lever Handles with a soft damp cloth every week to remove dust and stains. For Satin Stainless Steel surfaces, you can use a neutral detergent and warm water in a ratio of 1:10, wet a soft cloth and gently wipe, then wipe dry with a dry cloth. Tests show that after cleaning in this way, the stain removal rate on the handle surface can reach more than 95%, while avoiding corrosion of the surface by detergent residue. Avoid using rough cleaning tools or strong acid and alkaline cleaners to avoid damaging the surface treatment layer of the handle. Long-term adherence to the correct cleaning method can extend the service life of the handle and maintain its appearance and performance.

Moisture-proof treatment

Bathroom Door Lever Handles should be treated with moisture-proof treatment once a month. A thin layer of anti-corrosion oil or special metal protective wax can be applied to the surface of the handle. This protective layer can effectively isolate moisture from contacting the handle surface and prevent water vapor in humid air from corroding the handle. Tests show that handles treated with anti-corrosion oil showed no obvious rust on the surface after being placed in an environment with a humidity of 90% for 72 hours, while untreated handles showed slight signs of oxidation. In a humid bathroom environment, regular moisture-proof treatment can significantly improve the corrosion resistance of the handles and extend their service life.

Check screw tightening

Check the installation screws of the Bathroom Door Lever Handles every quarter to see if they are loose. If the screws are found to be loose, tighten them to a torque of 1.5 - 2 Nm with the matching wrench. For rusty screws, first clean the rust with a wire brush, then apply anti-rust grease and reinstall. During regular inspections, a hotel found that the screws of some bathroom door handles were loose. After tightening them in time, the stability of the handles was restored. If the loose screw problem is not handled in time, it may cause the handles to shift, affecting normal use, or even causing the handles to fall off, causing safety accidents.

Repair of surface scratches

If there are slight scratches on the surface of the Bathroom Door Lever Handles, they can be gently polished with a metal polish that matches the surface treatment of the handles and a soft cloth. Take the surface of Satin Stainless Steel as an example. Use a special stainless steel polisher to gently wipe along the direction of the scratches. After each wipe, wipe off the excess polisher with a dry cloth until the scratches fade or disappear. Tests show that after this method of treatment, the scratch fading rate can reach more than 80%, which can effectively restore the beautiful appearance of the handle. For deeper scratches, it is recommended to contact professional maintenance personnel in time for repair to avoid further expansion of the scratches and affect the performance and appearance of the handle.

Avoid contact with chemicals

During the use of Bathroom Door Lever Handles, try to avoid direct contact with corrosive chemicals such as strong acids, strong alkalis, and salts. If accidentally exposed to these chemicals, the handle surface should be immediately rinsed with plenty of water, cleaned with a neutral detergent, and then wiped dry with a dry cloth. Tests show that strong acidic detergents (pH value less than 3) will cause surface corrosion depth of 0.05 mm after contact with the handle surface for 10 minutes, while timely rinsing and cleaning can control the corrosion depth to less than 0.01 mm. By avoiding chemical contact and timely treatment, the surface treatment layer of the handle can be protected, damage due to chemical corrosion can be prevented, and the service life of the handle can be extended.

Regularly check the function

Every six months, conduct a comprehensive inspection of the switch function and flexibility of the Bathroom Door Lever Handles. During the inspection, you can gently rotate the handle to feel the smoothness of its rotation, and check whether the handle and the door lock fit tightly. If the rotation is not smooth or there is a jam, a small amount of special lubricant can be added to the rotating part of the handle, such as lubricant with a viscosity of ISO VG 32, and the amount of lubricant added is about 0.5 ml. Tests show that after adding lubricant, the rotation resistance of the handle can be reduced by about 60%, restoring its flexible operating performance. Through regular inspection and maintenance, it can be ensured that the handle always maintains a good working condition during long-term use, providing users with stability and efficiency of related equipment during operation.

Installing exterior lever door handles is typically straightforward. Most handles come with all necessary hardware and clear instructions. Simply follow the guidelines to fit the lever onto the door, making it an easy DIY project for homeowners or contractors.

Exterior lever door handles are commonly made from durable materials such as stainless steel, brass, and aluminum. These materials provide resistance to corrosion and wear, ensuring the handles can withstand various weather conditions while maintaining their appearance.

Exterior lever door handles are available in a variety of finishes, including polished chrome, brushed nickel, antique brass, and matte black. This range allows homeowners to choose a style that complements their exterior decor and enhances curb appeal.

Many manufacturers offer warranties for their exterior lever door handles, typically covering defects in materials or workmanship. Be sure to check the warranty details when purchasing to ensure you have coverage for your investment.

Yes, exterior lever door handles are well-suited for commercial use in offices, restaurants, and retail spaces. Their durability and ease of use make them ideal for high-traffic areas, ensuring reliable performance in demanding environments.