Square Bar Handles are square metal handles, usually used on surfaces that need to be held and operated, such as furniture, cabinets, doors and windows. It has a long square cross-section design with mounting interfaces at both ends. Different sizes can be selected according to specific needs, suitable for installation and use in a variety of application scenarios.

MATERIAL: The handles made of high quality Stainless Steel, they are hollow construction, lightweight but durable and anti-corrosive,can be used for many years.

MEASUREMENT: Please measure your size carefully and then decide which size is what you need.

TOP QUALITY & REASONABLE PRICE: Our pulls have smooth surface, that makes you feel comfortable in using, you don't have to worry about being scratched. Use these our goldenwarm hardware to decorate your home or update some old furniture, bring you a modern look.Very stylish and unique.

PACKAGE INCLUDE: Pack a pair pulls with matched standard screws with key. Every pull is individually wrapped and bagged to protect the beautiful color.

Black PVD

Polished Stainless steel

Satin Stainless steel

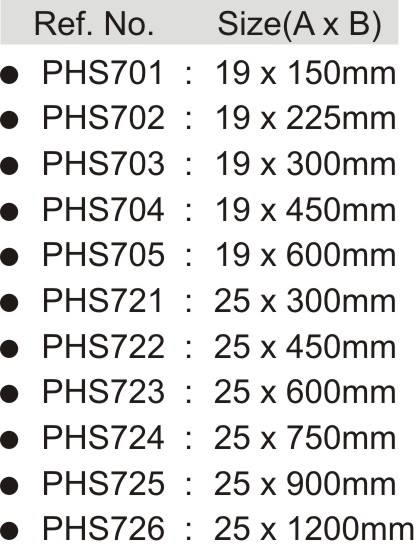

Size Diversity: Square Bar Handles offer a wide range of sizes, with lengths ranging from 150mm to 1200mm, and cross-sectional widths of 19mm and 25mm. For example, the PHS701 measures 19x150mm, while the PHS726 measures 25x1200mm. The length tolerance is controlled within the range of ±1.0mm, and the cross-sectional tolerance is ±0.2mm, ensuring precise matching with various opening sizes. The weight of each specification of handle ranges from 0.18kg (PHS701) to 2.1kg (PHS726), making it easy to choose the right model according to the load-bearing requirements.

Surface Material Selection: The handle surface treatment is available in three materials: Black PVD coated steel, polished stainless steel (304 grade) and brushed stainless steel (316 grade). The Black PVD coating is 5-8μm thick, the Vickers hardness reaches 800HV, and the adhesion test passed 50 times of tape sticking without falling off. The reflectivity of polished stainless steel surface is as high as 92%, and the roughness Ra value is less than 0.4μm; the texture spacing of brushed stainless steel is 0.25mm, the touch is delicate and the residual fingerprint visibility is less than 15%.

Structural firmness: The handle adopts a solid square cross-section design, and the wall thickness is uniformly 2.5-3.0mm, which can withstand a maximum vertical tension of 25kg without plastic deformation. The installation interface has been strengthened and can withstand repeated 15kg lateral force, and the swing angle test has reached 50,000 times without structural loosening. The connecting thread is M6 specification, and the tensile strength reaches 600MPa, ensuring stability in long-term use.

Surface precision: The surface treatment accuracy reaches ±0.1mm, and the edge is chamfered with R0.5mm, which not only retains the square contour but also avoids the risk of cutting hands. The surface roughness of the three materials is less than 0.8μm, among which the polished stainless steel can reach 0.4μm, and the touch is as smooth as a mirror. The results of the salt spray test show that the stainless steel material can be rust-free for up to 300 hours, and the Black PVD coating can withstand 480 hours of salt spray environment, meeting the requirements of different environments.

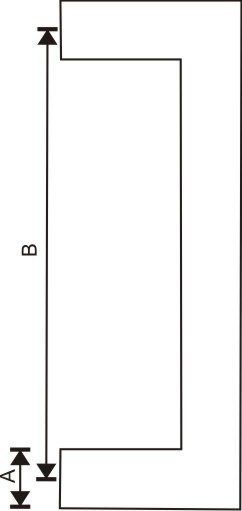

Installation flexibility: The standard configuration includes two mounting holes at the top and bottom, and the center spacing of the holes is in a 1:1 ratio with the handle length (for example, the 600mm spacing of PHS705). The mounting hole diameter is φ6.2mm, and the clearance with the M6 screw is less than 0.1mm. Optional extension brackets can be used to achieve multi-point fixation, and the bracket spacing can be adjusted from 50-300mm to meet the needs of various installation scenarios.

Protection performance: After rigorous environmental testing, the Black PVD coating can withstand temperature changes from -40℃ to +150℃, and the thermal expansion coefficient is 12.5×10⁻⁶/℃. The stainless steel material has passed the 300-hour salt spray test and has no signs of corrosion after being stored in an environment with a relative humidity of 95% for 14 days. The surface treatment complies with RoHS standards, and the heavy metal content is below the detection limit to ensure safe use.

Design compatibility: The handle design conforms to ergonomic principles. The 19mm wide version is suitable for users with palm thickness of 18-22cm, and the 25mm wide version is suitable for users with palm thickness of 22-25cm. The surface friction coefficient is 0.38-0.42, providing appropriate grip resistance. It matches the thickness of mainstream furniture door panels (16-22mm). After installation, the flatness error between the handle and the door surface is less than 0.2mm, enhancing the overall aesthetics.

High-end furniture manufacturing: Square Bar Handles are widely used in the production of custom cabinets and high-end wardrobes. Its square design is highly consistent with the modern minimalist style, especially in high-end furniture brands in Italy and Germany. The 25mm wide version is matched with solid wood door panels to enhance the overall texture. When installing, the size that matches the thickness of the door panel is usually selected. For example, the 19mm wide version is suitable for door panels with a thickness of 16-18mm to achieve a perfect visual proportion.

Precision equipment operation: This handle plays an important role in laboratory instruments and medical equipment. For example, on clean benches and analytical instruments, the PHS703 (19x300mm) size is suitable as a handle for the operating panel. Its non-reflective surface reduces light interference, and the precise dimensional tolerance ensures precise matching with the equipment opening. The installed handle is flush with the surface of the equipment, easy to clean and does not accumulate dust, in line with GMP and ISO 13485 standards.

Building interior decoration: In modern office and commercial buildings, Square Bar Handles are often used for glass partitions and metal decorative doors. The brushed stainless steel version is widely used on display cabinet doors in many retail stores. Its 25x600mm specification is matched with large glass doors to provide sufficient gripping area while maintaining visual simplicity. Concealed screws are used during installation, and the connecting parts are not visible from the outside, enhancing the overall design.

Transportation interior: This handle is specially selected in the design of lockers in high-speed trains and business class aircraft. The PHS702 (19x225mm) size is ergonomic and provides a comfortable grip experience in limited space. Vibration tests and accelerated fatigue tests are passed to ensure stability during transportation operation. The surface treatment meets flame retardant standards and meets the strict safety requirements of transportation interiors.

Industrial control panels: Square Bar Handles are ideal for control cabinets and distribution boxes in automated production lines. The long-size version of PHS724 (25x750mm) provides a stable grip point for large control panels. Its Black PVD material is resistant to oil stains and chemical solvents in industrial environments. The mounting interface can be used with standard DIN rails for quick assembly and disassembly, facilitating equipment maintenance and upgrades.

Exhibition display design: This handle is cleverly used in museum showcases and high-end brand display racks. The polished stainless steel version interacts with the display lights through mirror reflection to create a unique visual effect. For example, in jewelry showcases, the small-size version of PHS701 (19x150mm) is used with a small glass door to ensure safety without blocking the view of the exhibits. Precision positioning technology is used during installation to ensure that the coaxiality error between the handle and the door axis is less than 0.2mm, achieving a smooth opening experience.

Daily cleaning and maintenance: It is recommended to use a microfiber cleaning cloth to gently wipe the handle surface 1-2 times a week. For Black PVD material, a neutral detergent (such as a 3% mild detergent solution) should be used, and avoid using products containing chloride or abrasive ingredients. For polished stainless steel surfaces, a special stainless steel cleaner can be used, wiping in a single direction to maintain the mirror effect. Wipe with a dry cloth after each cleaning to prevent water stains from affecting the surface gloss.

Chemical environmental protection: When used in a laboratory or industrial environment, if it comes into contact with acidic and alkaline substances, it should be cleaned within 30 minutes. For contact with strong oxidizing chemicals, rinse immediately with plenty of clean water and use a special metal protective agent for repair. Establish a chemical contact record card to record in detail the time, type of substance and treatment measures for each accidental contact, so as to facilitate tracking of possible surface damage.

Physical protection measures: During transportation and installation, EVA protective covers should be put on both ends of the handle to prevent edge damage caused by collision. For the installed handle, a transparent protective film (light transmittance>90%) can be pasted on the surface. The recommended thickness of the protective film is 0.12-0.15mm, and it should be removed after 6 months of normal use. In high-traffic areas, anti-collision corners (matching the color of the handle material) can be installed to reduce the probability of accidental bumps.

Regular performance inspection: Check the installation fasteners of the handle every quarter, and use a torque wrench (set to 8-10N·m) to confirm the screw preload. For loose connection points, clean the impurities in the threaded hole first, then reinstall and apply an appropriate amount of thread lock glue. Check the gap between the handle and the installation base. The standard gap should be less than 0.3mm. If it exceeds this range, adjust the installation gasket or recalibrate the installation position.

Surface treatment and repair: When slight scratches are found on the surface, for brushed stainless steel, use an ultra-fine grinding sponge (grit 3000) in the same direction to gently treat it, and use a special brightener to restore the gloss. If the Black PVD coating is partially peeled off (area less than 5mm²), it can be repaired using cold welding technology and then polished with fine sandpaper to a smooth transition with the surrounding area. Establish a surface damage file to record the location and extent of each repair. When the same area is repaired more than 3 times, it is recommended to replace the handle.

Environmental control strategy: In the storage and use environment, the relative humidity should be controlled below 75%, and the temperature fluctuation range should be controlled within ±15℃. For long-term spare handles, they should be stored in a sealed plastic box with a desiccant, and the anti-rust oil layer (for stainless steel) or coating integrity (for PVD materials) should be checked every 6 months. In high humidity seasons, a dehumidifier can be used to maintain the dew point temperature of the storage space below -5℃ to prevent potential condensation erosion risks.